News & Events

The Complete Guide to 96 Well Plates for Laboratory Research

A 96 well plate is a flat plate with 96 small wells arranged in an 8 by 12 grid. You use this tool to test or analyze many samples at once. Scientists in microbiology rely on the 96 well plate to grow bacteria quickly and get reliable results. In cell culture, you can grow and study different cell types, which helps in cancer research. Many laboratories choose the 96-well plate for its efficiency and ability to handle multiple experiments. Proper selection, careful handling, and regular maintenance of your plates help ensure accurate and trustworthy results.

Key Takeaways

- A 96 well plate allows you to test multiple samples at once, saving time and reducing errors in laboratory experiments.

- Understanding the alphanumeric grid layout of a 96 well plate helps you track samples accurately and minimizes mistakes.

- Choosing the right material and surface treatment for your 96 well plate is crucial for achieving reliable results in your assays.

- Proper handling and cleaning of 96 well plates ensure accuracy and reproducibility in your experiments.

- To prevent edge effects and evaporation, fill outer wells with water and use sealing tape during incubation.

96 Well Plate Basics

What Is a 96 Well Plate

You use a 96 well plate in many laboratory experiments. This microplate has a standardized format that helps you work with multiple samples at once. Each plate contains 96 wells arranged in an 8 by 12 grid. You can see the uniform design in the dimensions. The plate measures about 85.48 mm in width and 127.76 mm in length. Automated systems can access each well because the spacing stays consistent. The height may change depending on your application, but the footprint always matches the standard.

| Specification | Value |

|---|---|

| Standardized Plate Dimensions | 85.48 mm ± 0.50 mm width |

| 127.76 mm ± 0.50 mm length | |

| Fixed Well Spacing | Ensures accurate access by automated systems |

| Consistent Height Variations | Varies by application needs, but conforms to footprint |

You find the 96 well plate in many research fields. You can use it for cell culture, sample storage, or high-throughput screening. The microplate format lets you run many tests at the same time. You save time and reduce errors when you follow the best practices for designing a 96 well plate layout.

96 Well Plate Layout

You need to understand the 96 well plate layout to get reliable results. The layout uses an alphanumeric grid. Rows go from A to H, and columns go from 1 to 12. You see wells labeled as A1, B2, or H12. This system helps you keep track of samples and reduces mistakes.

| Feature | Description |

|---|---|

| Standardized Design | The 96 well plate has a uniform arrangement in an 8×12 grid, facilitating easy referencing. |

| Alphanumeric Grid | Wells are labeled A1 to H12, which helps in minimizing errors during experiments. |

| Edge Effects Mitigation | Proper layout planning reduces edge effects and cross-contamination risks. |

Tip: You can minimize edge effects and cross-contamination by planning your 96 well plate layout carefully. Place controls and samples in a systematic way. Use consistent methods for pipetting and sample placement.

When you follow best practices for designing a 96 well plate layout, you lower the risk of experimental errors. You should always check your plate map before starting an experiment. Careful planning helps you avoid mixing up samples and keeps your data accurate.

- Systematic sample placement

- Careful experimental design

- Reduced edge effects and contamination

You improve your results when you understand the 96 well plate layout and use a systematic approach.

Applications of 96-Well Plates

You use a 96 well plate in many laboratory settings. This tool helps you run high-throughput experiments and analyze many samples at once. You see 96-well plate technology in molecular biology, clinical diagnostics, pharmaceutical research, and biomedical studies. The versatility of this format supports a wide range of assays, from chemical assays to protein analysis.

PCR and DNA Extraction

You rely on the 96 well plate for PCR and DNA extraction protocols. This format lets you amplify DNA samples and extract genetic material from many sources at the same time. You can process 96 samples in under three hours using a multi-channel pipette. The cost per sample stays low, around $0.20, which makes this method budget-friendly. The DNA you extract works well for PCR and matches the quality of commercial kits.

| Application Type | Description |

|---|---|

| PCR | Essential for amplifying DNA samples in a high-throughput format, allowing simultaneous analysis. |

| Sequencing | Enhances sequencing efficiency and reduces costs, facilitating precise genetic analysis. |

| Biomarker Research | Improves diagnostic capabilities by examining multiple biomarkers, crucial for various diseases. |

You can use this plate for sequencing and biomarker research. You improve throughput and reduce errors by handling many samples in parallel. You achieve high detection sensitivity and reliable results in genetic studies.

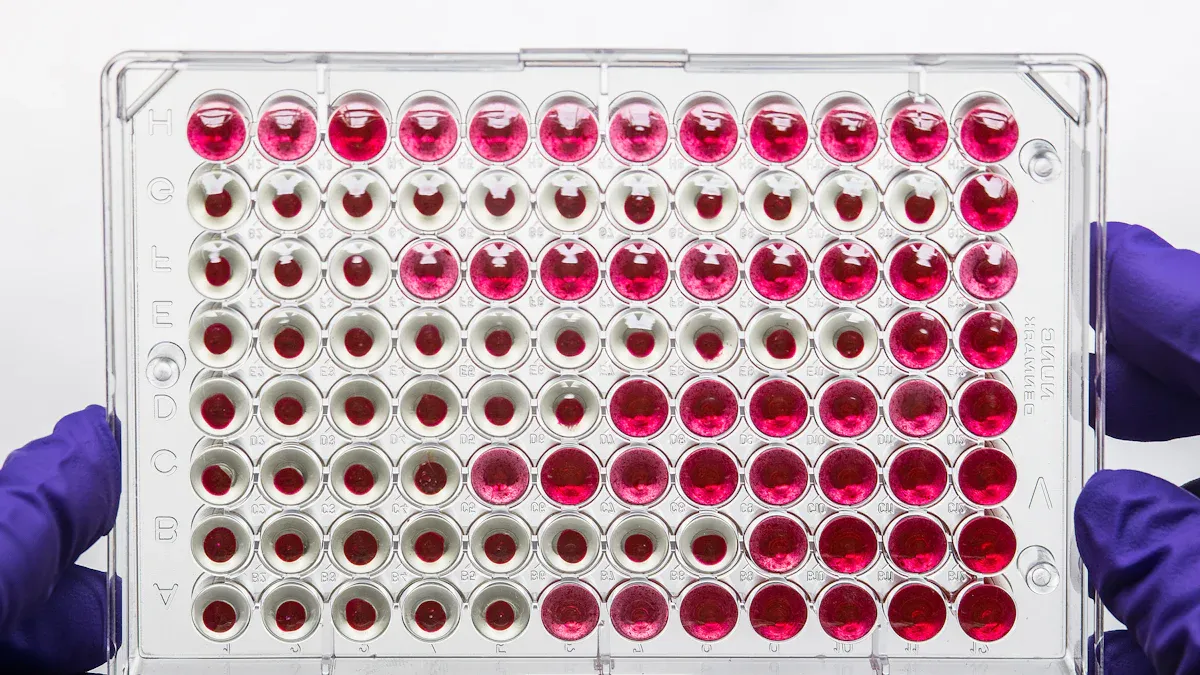

96-Well ELISA Plates

You use 96-well elisa plates for enzyme-linked immunosorbent assays. These plates help you detect proteins, antibodies, and antigens in clinical and research labs. You can test multiple samples at once, which increases throughput and saves time. The standardized design of 96-well elisa plates ensures reproducible results and high detection sensitivity.

| Feature | Benefit |

|---|---|

| Simultaneous Testing | Allows multiple samples to be tested at once, increasing throughput. |

| Standardization of Assays | Contributes to reliable and reproducible results, enhancing accuracy. |

| Precision | Daily fluctuations and different operators do not significantly affect assay variability. |

| High Throughput Capability | 140 samples can be assessed by one operator daily, facilitating efficient clinical testing. |

| Minimal Protocol Adaptation | Assays can be miniaturized on 384 well plates with minimal changes, supporting scalability. |

You can run enzyme-linked immunosorbent assays to measure proteins and antibodies in blood samples. You detect disease markers and monitor immune responses. You benefit from the ability to process 140 samples per day with one operator. You see consistent results even when different people run the assays. You can scale up to 384-well plates with minimal changes to your protocol.

Tip: You should place controls and standards in the same columns across plates. This practice helps you compare results and maintain accuracy in your enzyme-linked immunosorbent assays.

You use 96-well elisa plates to study proteins, antibodies, and antigens. You rely on their throughput and sensitivity for clinical diagnostics and research.

Cell Culture and Storage

You use 96 well plates for cell culture and sample storage. You can test many cell lines and conditions at once. The small well volume reduces waste and saves reagents. You run cytotoxicity tests, protein assays, and enzyme-linked immunosorbent assays in the same format. You can automate your workflow and scale up experiments easily.

| Advantage | Description |

|---|---|

| High-Throughput Testing | Allows testing of multiple samples simultaneously, saving time in experiments. |

| Reduced Waste | Smaller well volume minimizes reagent waste while still providing significant data. |

| Automation Compatibility | Compatible with automated systems, enhancing speed and accuracy of experiments. |

| Versatility in Assays | Suitable for various assays like ELISA, PCR, and cytotoxicity tests. |

| Scalability | Enables scaling up experiments and testing multiple variables within a single plate. |

- You can run multiple experiments on different cell lines at the same time.

- You gather better data in cell-based assays, which helps you compare results accurately.

- The uniform wells ensure that differences in results come from your experimental changes, not from plate design.

The design of 96 deep-well plates increases the surface area to volume ratio. You process more cells or molecules at once and maintain resolution. You improve your experimental design and data collection.

High-Throughput Screening

You use 96 well plates for high-throughput screening in pharmaceutical research. This format lets you test large chemical libraries quickly. You deposit compounds in the middle columns and place controls in the first and last columns. You seed HeLa cells at 36,000 cells per well in 90 µL of medium. You can run eight daily screening sessions and test 560 compounds in one week.

| Aspect | Description |

|---|---|

| Role of 96 well plates | Integral to high-throughput screening (HTS) in pharmaceutical research, serving as the main compound handling and screening format since the 1990s. |

| Miniaturization | Enables testing of large chemical libraries in a compact format, enhancing efficiency. |

| Automation | Facilitates lab automation and robotics, crucial for high-throughput processes. |

| Study | Findings |

|---|---|

| High-Throughput 96-Well Nanogroove-Enhanced Electrical Impedance Biosensor | Enhances precision and scalability for real-time monitoring of cellular behavior under drug exposure using 96-well plates. |

| Integrating in vitro metabolomics | Establishes a high-throughput metabolomics workflow compatible with 96-well plates, demonstrating sensitivity and repeatability in drug screening. |

- You use automation and robotics to handle plates and run high-throughput assays.

- You monitor cellular behavior and drug effects in real time.

- You achieve repeatable and sensitive results in metabolomics and drug screening.

You see 96 well plates in chemical assays, protein analysis, and antibody screening. You rely on their throughput and scalability to advance drug discovery and biomedical research.

Types of Microplates

Material and Surface

You choose the right material for your 96 well plate to match your experiment. Polystyrene and polypropylene are the most common materials. Each one affects your results in different ways.

| Material | Key Characteristics | Impact on Experimental Outcomes |

|---|---|---|

| Polystyrene | Excellent optical clarity, high binding capacity, compatible with various coatings | Ideal for assays requiring high detection sensitivity |

| Polypropylene | Less sensitive to temperature fluctuations, lower binding capacity | Suitable for harsher conditions but may affect sensitivity negatively |

Polystyrene gives you high binding capacity. You use it for high binding plates when you need to detect small amounts of protein. Polypropylene works better for storage or when you need to resist chemicals. You see lower binding with polypropylene, so you may lose sensitivity in some assays.

Surface treatments also change how your samples interact with the plate. You find high binding, medium binding, and non-binding surfaces.

| Surface Type | Description | Binding Capacity | Best Use Cases |

|---|---|---|---|

| High Binding Surface | Enhanced protein adsorption via hydrophobic interactions | ~400–500 ng IgG/cm² | Direct/indirect ELISAs, low concentration protein coating |

| Medium Binding Surface | Moderate protein binding, lower background in some assays | ~200–300 ng/cm² | Less “sticky” molecules |

| Non-binding Surface | Hydrophilic surface resists protein adsorption | N/A | Suspension assays, blocking experiments |

You select high binding plates for ELISA and protein assays. Medium binding plates help when you want less background. Non-binding plates work for suspension cells or when you want to block binding.

Tip: Always match the binding surface to your assay. High binding plates give you the best results for low concentration samples.

Well Shape and Volume

You notice that well shape and volume affect your experiment. Larger sample volumes help you pool samples better. Absolute volume loss stays about the same, between 150 and 230 µL per plate. The design and material of pooling lids also change how much liquid you recover. Surface wettability can trap water and cause sample loss.

- You get 93% recovery with a polystyrene injection molded lid.

- You get 90% recovery with a polycarbonate milled lid.

- Hydrophobic surfaces can trap water, lowering your recovery.

You pick the right well shape and volume to improve binding and sample recovery. Flat-bottom wells help with optical assays. Round-bottom wells help with mixing. You use high binding plates with flat wells for ELISA.

Plate Color Options

You use colored plates to improve your results in fluorescence and absorbance assays. Black plates reduce background noise and cross-talk between wells. This helps you get a better signal-to-blank ratio in fluorescence assays. White plates reflect light and boost signals in luminescence assays. Grey plates give you a balance, lowering cross-talk but keeping good signal quality.

Note: Choose black plates for fluorescence, white plates for luminescence, and grey plates for mixed applications.

You select the right color to match your detection method and improve binding results.

Shallow Storage Microplates

You use shallow storage microplates when you need to store or process small sample volumes. These plates help you save reagents and reduce waste. Shallow wells make it easier to recover samples and improve binding efficiency. You often use high binding plates in shallow formats for sensitive assays. Shallow plates also help you automate your workflow and speed up sample handling.

- Store small volumes with less waste.

- Improve sample recovery and binding.

- Use high binding plates for sensitive detection.

You match the microplate type to your experiment for the best results. The right choice improves binding, recovery, and data quality in every 96-well plate assay.

Choosing a 96 Well Plate

Application Fit

You need to match your 96 well plate to your experiment. Start by thinking about what you want to measure and how many samples you plan to test. Some plates work better for high-throughput screening, while others suit small-scale studies. If you use automation, check that your plate fits with your robotic systems. You should also look at how easy the plate is to use and if it supports your detection method.

| Criteria | Description |

|---|---|

| Detection modes | Make sure the plate supports absorbance, fluorescence, or luminescence as needed. |

| Throughput and capacity | Choose the number of wells and the throughput for your experiment. |

| Sensitivity and dynamic range | Pick a plate that can detect and measure your samples accurately. |

| Software and data analysis | Confirm that your data analysis software works with your plate. |

| Flexibility vs. specialization | Decide if you need a plate for one type of test or many. |

| Ease of use | Select a plate that is simple to handle and set up. |

| Automation and integration | Ensure the plate works with your lab’s automation systems. |

| Service and support | Look for good technical support and service options. |

Tip: Always review your experiment’s needs before you choose a plate. This step helps you avoid costly mistakes.

Assay Compatibility

You must check that your 96-well plate matches your assay and instruments. Some thermal cyclers need special plates, like full-skirted or low-profile types. If you use a plate that does not fit, you may get poor results or damage your equipment.

| Consideration | Description |

|---|---|

| Compatibility with Instruments | Make sure your plate fits your thermal cycler or reader. Some machines need specific plate types. |

You should also think about the chemicals and samples you use. Some plates work better with certain reagents or sample types. Always check the manufacturer’s guide for compatibility.

Supplier and Cost

You want a reliable supplier for your 96-well plate. Look for companies with strong technical support and fast delivery. Compare prices, but do not pick only the cheapest option. Quality matters for your results. Some suppliers offer service contracts or bulk discounts, which can help your lab save money over time.

- Check for warranty and return policies.

- Ask about technical help and training.

- Review customer feedback and ratings.

Note: A good supplier can help you solve problems quickly and keep your experiments on track.

Best Practices for 96-Well Plates

Handling and Pipetting

Proper handling of your 96 well plate is key to achieving accuracy and reproducibility. You should always use the right pipette and tips for your sample volume. This helps you avoid errors and ensures consistent results. Here are expert tips for maximizing accuracy:

- Select a pipette with a volume range close to your sample size.

- Use high-quality tips designed for your pipette.

- Minimize handling time to keep the plate at a stable temperature.

- Hold the pipette at a 10-45 degree angle and touch the tip to the well wall.

- Wait a second before fully dispensing to let all liquid leave the tip.

To follow best practices for handling 96-well plates, always set the pipette volume first, depress the plunger, immerse the tip, and release the plunger slowly. Slide the tip up the well wall to remove any leftover liquid.

You should also pay attention to your posture and grip. This reduces strain and helps you maintain steady hands during handling.

Cleaning and Storage

Cleaning and sterilizing 96-well plates keeps your experiments reliable. After each use, discard any leftover liquid and rinse every well with distilled water. Soak the plate in a mild lab detergent to remove residues. For stubborn spots, use a soft brush or ultrasonic cleaner. Rinse several times with distilled water to remove detergent traces. Let the plate air dry in a dust-free place or use a low-lint cloth.

For sterilization, you can use UV light for 15-30 minutes or soak the plate in 70% ethanol. If your plate can handle heat, use a dry-heat sterilizer at 160°C for two hours. Always check the plate for cracks or cloudiness. Replace plates that show damage to maintain accuracy.

Store plates in optimal storage conditions—keep them dry, covered, and away from direct sunlight.

Preventing Contamination

Cross-contamination can ruin your results. You can prevent this by randomizing samples across plates and avoiding the processing of samples with different biomasses together. Manual single-tube extractions also help reduce risk.

- Cover the 96-well plate with PCR sealing tape.

- Peel back the tape only when you need to access a well.

- Keep wells covered during sample loading.

Using barcoded tubes for sample processing can further lower the chance of cross-contamination. Always follow best practices to keep your results trustworthy.

Troubleshooting 96 Well Plates

Edge Effects

Edge effects often cause problems in 96 well plate experiments. You may notice that wells along the edges behave differently than those in the center. This happens because evaporation affects the outer wells more, changing the concentration of your samples. Even three rows inward can show these changes. Different brands of plates can also show different levels of edge effects and evaporation.

| Issue | Description |

|---|---|

| Edge Effect | Frequently observed in multiwell plates, affecting results up to three rows inward. |

| Evaporation | Corner and edge wells are more prone to evaporation than interior wells. |

| Manufacturer Variability | Different brands of plates yield varying results regarding edge effects and evaporation. |

| Mitigation Strategies | Adding liquid between wells can help reduce edge effects; rewrapping does not prevent it. |

To reduce edge effects, you can:

- Use sealing tape for biochemical assays or breathable tape for cell-based assays.

- Place a low evaporation lid on your plate.

- Shorten assay time to limit evaporation.

- Leave outer wells empty or fill them with water or PBS.

Tip: Avoid stacking plates during incubation. This helps keep temperature even and reduces evaporation.

Inconsistent Results

You may see inconsistent results if edge effects or evaporation change the conditions in your wells. Outer wells lose water faster, which changes nutrient levels and pH. This can affect cell growth and lead to unreliable data in tests like PCR, ELISA, or Western blots.

To improve consistency:

- Fill outer wells with water or buffer to act as a barrier.

- Use specialized plates designed to limit evaporation.

- Keep incubation times short and avoid temperature swings.

Note: Inconsistent results often mean you need to check your plate setup and environmental controls.

Plate Damage

Physical damage to your 96 well plate can ruin your experiment. Cracks, scratches, or cloudy wells can cause leaks or interfere with readings. Always inspect your plates before use. Discard any plate that shows signs of damage.

- Handle plates gently to avoid bending or dropping them.

- Store plates in a dry, covered place away from sunlight.

- Use only recommended cleaning methods to prevent surface damage.

You protect your results when you care for your plates and watch for common issues.

Choosing the right 96 well plate and following best practices help you collect reliable data in your experiments. You improve data quality by wearing gloves, labeling carefully, and avoiding overfilling. Regular calibration and monitoring also support consistent results.

| Quality Control Practice | Impact on Reliability |

|---|---|

| Regular calibration verification | Ensures consistent performance |

| Systematic monitoring | Identifies issues early |

| Baseline measurements | Tracks data quality over time |

Understanding plate types, layout, and maintenance lets you work efficiently and keep your data accurate.

FAQ

What is the best way to label a 96 well plate?

You should use the alphanumeric grid (A1 to H12) printed on the plate. Write your sample names on a plate map before starting. This helps you avoid mix-ups and keeps your experiment organized.

How do you prevent evaporation in outer wells?

Fill the outer wells with sterile water or buffer. Use sealing tape or a lid to cover the plate. Shorten incubation times to reduce evaporation. This keeps your samples stable and improves your results.

Can you reuse 96 well plates?

You can reuse plates for non-critical assays after cleaning with lab detergent and rinsing with distilled water. Always check for cracks or cloudiness. Replace plates if you see any damage to avoid errors.

What is the difference between polystyrene and polypropylene plates?

| Material | Use Case | Key Feature |

|---|---|---|

| Polystyrene | Protein assays, ELISA | High optical clarity |

| Polypropylene | Sample storage, harsh chemicals | Chemical resistance |

Choose polystyrene for detection assays. Use polypropylene for storage or chemical exposure.

How do you avoid cross-contamination?

Tip: Always use fresh pipette tips for each sample. Cover the plate with sealing tape. Process samples in a clean area. Barcode tubes help track samples and lower contamination risk.