News & Events

Simple Steps to Maintain Your MyPipette System

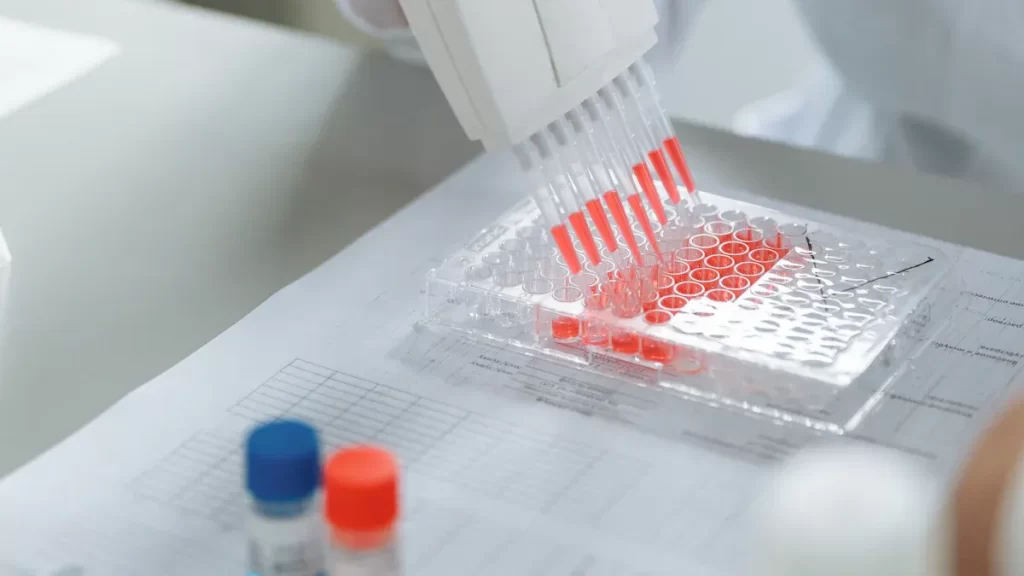

You can keep your mypipette system working well by following a few simple steps. Clean your pipettes often. Check them for damage or leaks. Test them to make sure they measure correctly. Regular care helps you get accurate results in immunoprecipitation. You also meet lab standards and help your pipettes last longer. Anyone in the lab can start these easy habits.

Key Takeaways

- Regularly clean your pipettes after each use to prevent contamination and ensure accurate results.

- Set a calibration schedule for your pipettes to maintain accuracy and meet lab standards.

- Inspect your pipettes frequently for wear and damage to catch problems early and avoid costly errors.

- Perform functional tests on your pipettes to check for leaks and ensure they deliver the correct volumes.

- Make pipette maintenance a habit to extend the life of your equipment and improve your lab’s efficiency.

Why Pipette Maintenance Matters

Reliable Results

You want your experiments to give accurate and reliable results every time. Regular pipette maintenance helps you achieve this goal. When you clean and calibrate your pipettes, you reduce the risk of measurement errors. Neglecting pipette care can cause inaccurate volumes, which may skew your results and lead to invalid conclusions. A study in the Journal of Analytical Chemistry found that many errors in lab results come from uncalibrated pipettes. If you use your mypipette system for immunoprecipitation, you need to trust your measurements. Routine maintenance supports accuracy and keeps your data strong.

Tip: Always check your pipettes before starting a new experiment. This habit helps you catch problems early and avoid wasted time.

Reducing Errors

Mistakes in pipetting can ruin your experiments. You can lower error rates by following a regular maintenance schedule. A 2023 survey showed that 18% of failed experiments were caused by pipette operation errors, and most of these errors came from not following proper procedures. Only a small number of pipette failures are easy to spot. Most problems happen inside the pipette’s sealing system, which you cannot see without inspection. By keeping your pipettes in good condition, you prevent spills, exposure to hazardous materials, and costly delays. You also meet important standards like cGLP, cGMP, and ISO 8655, which require regular calibration and documentation.

- Regular calibration and cleaning

- Proper training for all users

- Keeping detailed records

Extending Pipette Life

You save money and time when you take care of your pipettes. Maintenance extends the life of your equipment. Calibration ensures your pipettes deliver the right volume over time. Internal cleaning removes residue that can affect performance. Storing pipettes properly reduces stress and contamination risks. If you ignore maintenance, your pipettes may break down more often, leading to higher replacement costs and more downtime. Laboratories that follow maintenance protocols spend less on repairs and replacements. You help your lab stay efficient and avoid penalties or funding loss by keeping your pipettes in top shape.

- Calibration keeps accuracy high

- Cleaning prevents buildup

- Storage protects your pipettes

MyPipette Calibration

Calibration Schedule

You need to set a regular calibration schedule for your pipettes. This schedule helps you meet calibration requirements and keeps your mypipette system working well. ISO 8655 sets the standard for calibration frequency in labs. Most labs calibrate pipettes every three to six months, but you should check your lab’s specific calibration requirements. If you use pipettes for critical tasks like immunoprecipitation, you may need to calibrate more often.

Calibration frequency depends on how often you use your pipettes and the type of experiments you run. High-throughput labs often set shorter intervals. You can use calibration management software to automate scheduling. This software sends alerts when it is time to calibrate, so you never miss a calibration date. Automated scheduling increases productivity and helps you stay compliant with regulations.

Tip: Use RFID tags and handheld readers to track pipette calibration history. Automated alerts remind you when calibration is due.

Calibration Process

You must follow a clear calibration process to ensure accuracy. The calibration steps include several actions that help you calibrate the pipette correctly. Gather calibration tools before you start. Prepare the pipette by cleaning and inspecting it. Check the pipette’s accuracy by dispensing known volumes and measuring them. Adjust the pipette if you find errors. Repeat the process to confirm results. Record all calibration data for compliance. Regularly recalibrate the pipette to maintain accuracy.

Standard Calibration Steps for MyPipette Systems:

- Gather necessary materials and calibration tools.

- Prepare the pipette for testing.

- Check the pipette’s accuracy by dispensing and measuring.

- Adjust the pipette if needed.

- Repeat the calibration process to confirm accuracy.

- Record the results in your documentation system.

- Regularly recalibrate the pipette according to your schedule.

Regular calibration reduces measurement errors in your workflow. You identify and correct volume delivery problems, which keeps your data reliable. Calibration also stops errors from spreading through your experiments. You support reproducibility and meet regulatory standards by following calibration requirements.

- Calibration ensures pipettes deliver exact volumes every time.

- You avoid flawed data and keep your results valid.

- Consistent calibration practices protect the integrity of your research.

If you use calibration management software, you gain several benefits:

- Automation tracks and manages calibration for all pipettes.

- Compliance improves because the software documents every calibration process.

- Efficiency increases as you streamline procedures and record results.

- Documentation provides proof of calibration for audits.

- Consistency in calibration steps helps maintain quality control.

- Automatic scheduling keeps you on track with calibration frequency.

- Real-time tracking shows you the status of each pipette.

- Cost savings come from eliminating paper records and automating tasks.

Accurate records of calibration, maintenance, and usage are essential for regulatory compliance. You can store calibration history and maintenance records with RFID tags. Automated alerts notify you when calibration is due, so you never miss a deadline.

Note: Calibration acts as a defense against inaccuracies. It ensures precision in measurements and supports reproducibility in immunoprecipitation assays.

Improper calibration can lead to flawed data and inconsistent volumes. This variability can affect your ability to reproduce results and may impact drug development or clinical trials. You must calibrate your pipettes regularly to protect the quality and reliability of your research.

Pipette Maintenance Steps

Keeping your pipettes in top condition means following a few core actions. You need to focus on cleaning, visual inspection, and functional testing. These steps help you maintain accuracy, avoid cross-contamination, and extend the life of your equipment. You also meet compliance standards and improve your lab’s workflow.

Cleaning Pipettes

You should clean your pipettes after every use. This habit prevents contamination and keeps your results reliable. For effective cleaning, use Liquinox Critical Cleaning Detergent or Alconox Powdered Precision Cleaner in a 1% solution. You can also use Alcotabs Critical Cleaning Detergent Tablets in a siphon washer. Always immerse your pipettes fully in the cleaning solution to protect all components.

When you clean your pipettes, pay special attention to serological pipettes. These tools often handle sensitive samples, so regular cleaning is vital. If you use serological pipettes for different tasks, label them to avoid cross-contamination. Never use pipettes that look broken or have been dropped.

Tip: Follow the manufacturer’s instructions for specific maintenance procedures. This step helps you avoid damage and keeps your pipettes working well.

You can also schedule preventative maintenance with professional services. These services use advanced cleaning methods and check for hidden problems. Preventative maintenance reduces downtime and increases the lifespan of your mypipette system.

Visual Inspection

You need to inspect your pipettes regularly. Look for signs of wear, corrosion, or residue. Regular inspection helps you spot problems before they affect your results. Check the seals, tips, and barrels for cracks or buildup. If you see any damage, remove the pipette from use and report it.

- Regular visual inspections are crucial for identifying wear, corrosion, and potential failures in pipettes.

- Always check serological pipettes for residue or discoloration.

- Label pipettes based on their intended use to avoid cross-contamination.

Daily maintenance tips include wiping down the exterior and checking for leaks. If you notice sticky operation or loose parts, schedule a repair. Regular inspection supports accuracy and helps you meet industry standards.

Functional Testing

You should test your pipettes to make sure they work correctly. Functional testing checks for leaks and measures accuracy. Start by pre-wetting the tip three times. Aspirate the nominal volume and hold the pipette vertically with the tip immersed 2 mm in liquid for 30 seconds. If the liquid level drops, you have a leak.

Next, perform at least four measurements at 100% of the nominal volume. Repeat the test at 10% of the nominal volume. Record your results and compare them to the expected values. If you find errors, recalibrate the pipette or schedule a professional calibration.

Here is a simple checklist for functional testing:

- Pre-wet the tip three times.

- Aspirate and dispense the nominal volume.

- Hold the pipette vertically with the tip in liquid for 30 seconds.

- Check for leaks.

- Measure at 100% and 10% of the nominal volume.

- Record and review your results.

Functional testing is important for both manual and electronic pipettes. Manual pipettes are easier to repair, but electronic pipettes need battery checks and more frequent calibration. The table below shows the differences:

| Type of Pipette | Maintenance Requirements | Complexity Level |

|---|---|---|

| Electronic Pipettes | Require regular maintenance and calibration due to complex components and battery checks. | High |

| Manual Pipettes | Require regular calibration and maintenance but are simpler and easier to repair. | Low |

You can improve your skills with training from Artel or the Sartorius Pipetting Academy. These programs teach you about pipette mechanics, proper technique, and best practices for maintenance of serological pipettes. Training helps you avoid common user errors, such as skipping regular cleaning or using damaged pipettes.

Note: Preventative maintenance services help you reduce downtime, increase accuracy, and extend the lifespan of your pipettes. Regular maintenance also lowers long-term costs and improves data quality.

By following these daily maintenance tips and specific maintenance procedures, you keep your pipettes accurate and reliable. You also avoid cross-contamination and support compliance with industry standards. Make regular cleaning, inspection, and functional testing part of your routine for the best results in your lab.

Pipettes in Immunoprecipitation

Workflow Optimization

You can improve your immunoprecipitation workflow by caring for your pipettes every day. Clean serological pipettes before and after each use. This step helps you avoid contamination and keeps your results clear. When you check your pipettes for leaks or residue, you catch problems early. You also protect the accuracy of your measurements. Use a pipette that fits the volume you need. This choice reduces errors and saves time.

Tip: Label your serological pipettes for specific tasks. This habit prevents mix-ups and keeps your workflow smooth.

A well-maintained pipette gives you consistent results. You can trust your data when you know your pipettes work as they should. Many labs use a checklist to track cleaning and testing. This simple tool helps you remember each step and keeps your workflow organized.

Adapting Maintenance

High-throughput labs need special care for their pipettes. You may use many serological pipettes each day. Set up a rotation system so you always have clean pipettes ready. Schedule regular maintenance for all pipettes, not just the ones you use most.

Specialized labs may need extra steps. If you work with sensitive samples, test the accuracy of your pipettes more often. Keep a log of each pipette’s performance. This record helps you spot trends and fix issues fast.

| Lab Type | Maintenance Focus | Frequency |

|---|---|---|

| High-throughput | Cleaning, rotation | Daily |

| Specialized | Accuracy testing, logging | Weekly or as needed |

You can ask your team to share tips for keeping serological pipettes in top shape. When everyone follows the same steps, you get better results. Good maintenance supports accuracy and helps your lab meet high standards.

Troubleshooting Pipette Issues

Inconsistent Volumes

You may notice that your pipettes sometimes deliver different volumes, even when you use the same settings. This problem can affect the accuracy of your results, especially in immunoprecipitation experiments. Many factors can cause inconsistent volumes. The table below shows the most common errors and their descriptions:

| Common Error | Description |

|---|---|

| Inconsistent Pipetting Depth | Variation in depth during aspiration can lead to volume inconsistencies due to pressure changes. |

| Poor Tip Seal | A poorly seated pipette tip can cause significant volume inaccuracies. |

| Variation in Pipetting Speed | Different speeds during aspiration or dispensing can result in uneven liquid volumes. |

| Tip Contact | Contact with the bottom of wells can block the tip opening, leading to incorrect volumes. |

| Heat Transfer | Hand warmth can affect air pressure in the pipette, impacting accuracy over time. |

You should also watch for these issues:

- Tip quality and fit can change how much liquid you draw.

- Contamination may affect sample accuracy.

- High viscosity samples may not flow evenly.

- Calibration problems can lead to errors.

- User technique and environmental factors like temperature and humidity can impact consistency.

If you see inconsistent volumes, check your serological pipettes for tip fit and quality. Make sure you follow the same technique each time. Regular calibration helps you catch problems early and keeps your pipette working well.

Sticky Operation

Sticky operation makes it hard to move the plunger smoothly. This issue can lower accuracy and slow down your workflow. You can fix sticky operation by following these steps:

- Clean the piston and plunger with a lint-free cloth.

- Lubricate the plunger using a small amount of silicone grease or an approved lubricant.

- Spread the lubricant evenly and avoid using too much.

- Make sure the pipette is clean and dry before you apply lubricant.

If the sticky feeling does not go away, you may need professional maintenance. Regular cleaning and lubrication help your serological pipettes work smoothly. Always follow the manufacturer’s guidelines for best results.

Tip: Lubricate the plunger regularly to keep your pipette moving easily and maintain accuracy.

When to Service

You need to know when your pipettes require professional servicing. Look for these signs:

- Calibration checks show errors or drift.

- Accuracy and precision do not meet your lab’s standards.

- Preventive maintenance is overdue.

- Lubrication and seal replacement are needed.

You should use gravimetric or photometric methods to verify accuracy. Schedule regular maintenance for all serological pipettes. Professional servicing helps you avoid breakdowns and keeps your pipette system reliable.

Note: Regular calibration and maintenance protect your results and extend the life of your pipettes.

Regular calibration and maintenance of your mypipette system bring many benefits to your lab. You improve accuracy and precision, which helps you get reliable results. You also meet quality control standards and reduce the risk of cross-contamination. Good pipette care saves time and money by catching problems early and extending the life of your pipettes. When you make calibration and cleaning part of your routine, you support compliance and keep your workflow efficient.

- Accurate measurements and proper pipette care help you avoid repeated experiments.

- Routine calibration and maintenance keep your pipettes ready for every task.

Make pipette care a habit to protect your results and your equipment.

FAQ

How often should you clean your pipettes?

You should clean your pipettes after every use. This habit helps prevent contamination and keeps your results accurate. Always follow the cleaning instructions from the manufacturer.

What should you do if your pipette leaks?

Stop using the pipette right away. Check for cracks or worn seals. Clean the pipette and replace any damaged parts. If the leak continues, schedule professional maintenance.

Can you calibrate pipettes yourself?

You can perform basic calibration checks in your lab. For full calibration, use certified calibration services or follow your lab’s standard operating procedures. Always record your calibration results.

Why does your pipette feel sticky when you use it?

A sticky pipette often means the plunger or piston needs cleaning or lubrication. Clean these parts with a lint-free cloth. Use a small amount of approved lubricant if needed.

What records should you keep for pipette maintenance?

Keep a log of cleaning, calibration, and repairs for each pipette. This record helps you track performance and meet lab standards. Use digital tools or paper logs as needed.