News & Events

Exploring the Most Popular Test Tube Racks for Western Blotting

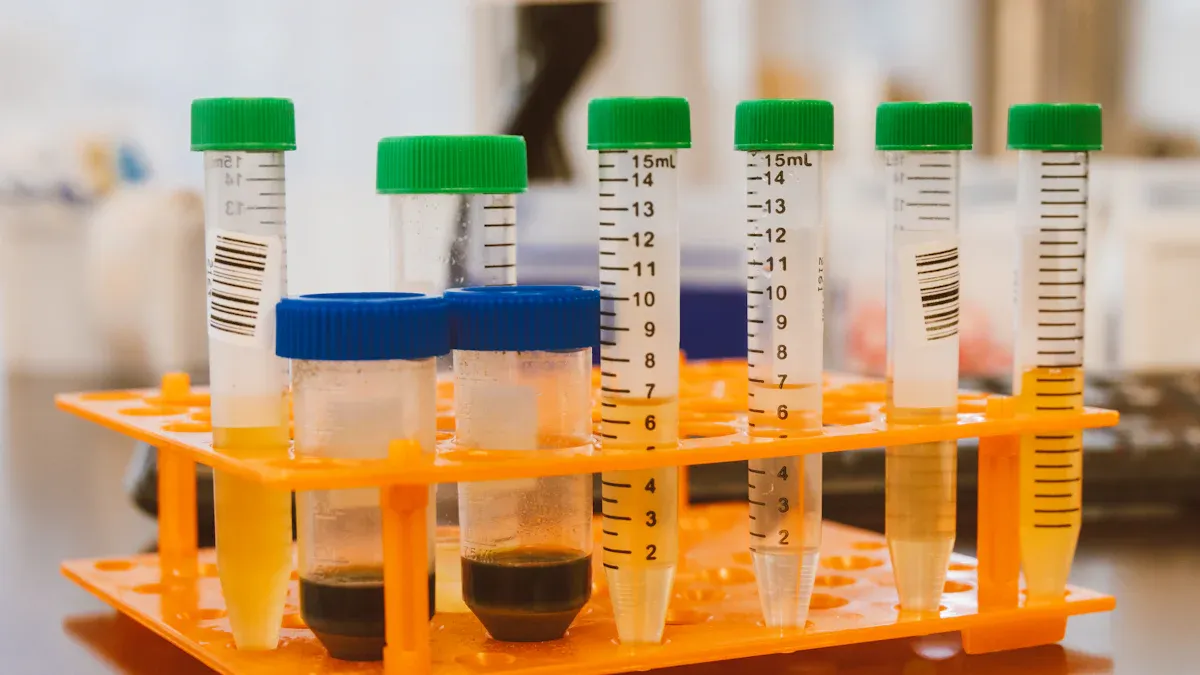

You often see the classic plastic or stainless steel test tube rack in Western Blotting labs. Choosing the right laboratory equipment matters. Racks keep your samples safe and organized. You can label or color-code them for easy tracking. This simple tool helps you process many samples at once. It also stops tubes from rolling or falling, which lowers the risk of accidents or contamination.

Key Takeaways

- Choose the right test tube rack to keep your samples organized and safe during Western Blotting.

- Select racks with molded alphanumeric grids for quick sample identification and to avoid mix-ups.

- Opt for autoclavable polypropylene or stainless steel racks for durability and easy sterilization.

- Consider stackable or interlocking racks to save space in busy labs while maintaining workflow efficiency.

- Regularly inspect and clean your racks to ensure safety and prevent contamination in your experiments.

Popular Test Tube Racks

Top Choices for Western Blotting

When you set up your Western Blotting workflow, you see many test tube racks in the lab. Some models stand out because experts and lab supply companies recommend them often. You can find racks like the R1115 and R1117 in many labs. These racks hold a large number of tubes and help you keep samples organized.

| Model | Description | Capacity | Price |

|---|---|---|---|

| R1115 | 90-Place Rack for 12-14mm Tubes | 90 | $52.68 |

| R1117 | 60-Place Rack for 15-17mm Tubes | 60 | $52.68 |

You also see Snap-N-Racks and Grip Racks in Western Blotting labs. Snap-N-Racks give you an economical choice. Grip Racks offer an innovative design. Many labs choose racks with molded alphanumeric grids. These grids help you identify samples quickly. You can pick from a broad selection of styles and sizes to fit your needs.

Tip: Choose racks with molded grids if you want to avoid mix-ups during busy experiments.

Key Features

You want test tube racks that last and keep your samples safe. Many labs use racks made from autoclavable polypropylene. This material lets you sterilize racks at 121°C (250°F) with steam. You also find steel test tube racks with epoxy coatings. These racks resist chemicals and corrosion, so you can use them with harsh reagents.

| Feature | Description |

|---|---|

| Autoclavability | Steam autoclavable at 121°C (250°F) |

| Chemical Resistance | Polypropylene and epoxy-coated steel test tube racks resist chemicals well. |

| Modularity | Interlocking feet let you stack racks and save space. |

Steel test tube racks work well for heavy use. You can stack them or choose extra-long sizes for more tubes. Many racks come in two sizes: 90-place and 60-place. You can assemble some racks easily, which saves you time. When you select test tube racks, look for features that match your workflow and sample volume.

Why Test Tube Racks Matter

Workflow Efficiency

You want your lab work to move smoothly. A good test tube rack helps you do this. When you set up your samples, you can place each tube in its own spot. This keeps everything in order. You do not waste time searching for the right tube. You can label each row or column, so you know where each sample goes. Many racks have numbers or letters to help you track samples fast.

Tip: Use color-coded racks to sort samples by experiment or date. This makes your workflow even faster.

You can also stack some racks. This saves space on your bench. You can move racks from one station to another without mixing up your samples. Many labs report that using organized racks cuts down on mistakes and saves time during busy Western Blotting runs.

Sample Safety

You need to keep your samples safe. A sturdy rack stops tubes from tipping over. This lowers the risk of spills or broken glass. If you use chemicals, racks made from strong materials protect your samples from damage. Polypropylene racks resist most lab chemicals. Steel racks hold up under heavy use.

A test tube rack also keeps your samples away from the edge of the bench. This helps prevent accidents. You can autoclave many racks to keep them clean and free from germs. Clean racks mean safer samples and better results.

| Safety Feature | Benefit |

|---|---|

| Stable Base | Prevents tipping and spills |

| Chemical Resistance | Protects against harsh agents |

| Autoclavable | Allows for easy sterilization |

You protect your work and your results when you use the right rack. This simple tool makes a big difference in your lab.

Types of Test Tube Racks

You have many options when you look at the types of test tube racks for Western Blotting. Each type has a unique design and purpose. Choosing the right one helps you organize your samples and improve your workflow.

Classic Racks

Classic racks are the most familiar among the types of test tube racks. You see them in almost every lab. These racks have a simple, rectangular frame with holes for tubes. You can find them in plastic, stainless steel, or even wood. Classic racks hold tubes upright and keep them separated.

Pros:

- Easy to use and clean

- Stable and sturdy

- Available in many sizes

Cons:

- Take up more space on the bench

- Wooden racks are hard to sterilize

Note: Classic wooden racks look vintage, but you may want to avoid them. Wood is hard to sanitize and can absorb chemicals.

Stackable and Interlocking Racks

Stackable and interlocking racks help you save space. You can stack them on top of each other or connect them side by side. These types of test tube racks work well in busy labs with limited bench space.

| Feature | Description |

|---|---|

| Stacking Capability | Lets you stack racks securely, saving space |

| Identification | Alpha numeric indexing for easy sample tracking |

| Material | Sturdy, chemical-resistant polypropylene |

| Autoclavable | Can be sterilized at 121ºC (250ºF) |

| Dimensions | Fits tubes up to 10cm (4″) long |

Pros:

- Save space by stacking

- Easy to expand for more samples

- Strong and chemical-resistant

Cons:

- May become unstable if stacked too high

- Some models only fit certain tube sizes

Tip: Use racks with alphanumeric grids. You can track your samples faster and avoid mix-ups.

Slant and Drying Racks

Slant racks hold tubes at an angle. This makes it easy for you to add or remove samples quickly. Drying racks let you air-dry tubes after washing. Both types of test tube racks serve special roles in Western Blotting.

| Type of Rack | Description | Material Considerations |

|---|---|---|

| Slanted Racks | Hold tubes at an angle for easy access | Plastic or metal |

| Drying Racks | Designed for drying tubes after washing | Metal or plastic |

Pros:

- Slant racks give you fast access to samples

- Drying racks keep tubes clean and dry

Cons:

- Slant racks may not fit all tube sizes

- Drying racks take up extra space

Note: You can use slant racks during sample prep. Drying racks help you keep your tubes ready for the next experiment.

PCR Tube Racks

PCR tube racks are a special category among the types of test tube racks. You use them for small tubes, like 0.2 mL or 0.5 mL PCR tubes. These racks have small holes and tight spacing. You often need them for Western Blotting steps that use PCR tubes for sample prep or reagent mixing.

Pros:

- Hold many small tubes securely

- Prevent loss or mix-up of tiny samples

- Often color-coded for easy sorting

Cons:

- Only fit PCR tubes, not larger tubes

- Some models are not autoclavable

Tip: Choose PCR tube racks made from polypropylene. You can autoclave them and use them with most chemicals.

Comparing the Types

Here is a quick overview of the main types of test tube racks you might use:

| Type of Rack | Description | Best Use in Western Blotting |

|---|---|---|

| Classic Racks | Upright, simple design | General sample storage |

| Stackable Racks | Stack to save space | High-throughput labs |

| Interlocking Racks | Connect to expand capacity | Flexible sample organization |

| Slant Racks | Hold tubes at an angle | Fast sample access |

| Drying Racks | Dry tubes after washing | Post-wash sample prep |

| PCR Tube Racks | Hold small PCR tubes | PCR-based sample prep or reagent mixing |

You should also consider the benefits of steel wire test tube racks. These racks resist corrosion and heat. You can autoclave them many times. The benefits of steel wire test tube racks include long life and easy cleaning. They work well for heavy use and harsh chemicals.

When you choose among the types of test tube racks, think about your workflow. You may need more than one type. PCR tube racks help you with small-volume tasks. Stackable racks give you more space. Classic racks offer stability. Each type supports a different part of your Western Blotting process.

Test Tube Rack Materials

Choosing the right material for your test tube rack can make your Western Blotting work safer and easier. Each material offers different strengths for durability, chemical resistance, and cleaning.

Plastic (Polypropylene, PTFE, Acrylic)

You often see plastic racks in labs because they are light and easy to handle. Polypropylene stands out as a top choice. It resists most chemicals and can handle high heat, so you can autoclave it for sterilization. Polypropylene racks do not rust or corrode, and you can take them apart for deep cleaning. PTFE and acrylic racks also appear in some labs. PTFE resists almost all chemicals, but it costs more. Acrylic racks look clear and neat, but they can crack if dropped.

| Material | Durability | Chemical Resistance | Autoclavable |

|---|---|---|---|

| Polypropylene | High, but brittle in cold | Highly resistant | Yes |

| PTFE | Excellent | Excellent | Yes |

| Acrylic | Moderate, can crack | Moderate | No |

Tip: Use polypropylene racks if you need a strong, chemical-resistant, and easy-to-clean option for daily Western Blotting.

Metal (Stainless Steel, Epoxy-Coated, Aluminum)

Metal racks give you strength and long life. Stainless steel racks resist corrosion and most lab chemicals. You can clean them easily, and they last for years. Epoxy-coated racks add extra protection against harsh chemicals and moisture. Both types work well in busy labs. Aluminum racks weigh less, but they do not last as long and may not resist chemicals as well.

| Material | Durability | Chemical Resistance | Cleaning Ease |

|---|---|---|---|

| Stainless Steel | Excellent | Good | Moderate |

| Epoxy-Coated | Excellent | High | Moderate |

| Aluminum | Good | Fair | Moderate |

Note: Stainless steel and epoxy-coated racks stay strong even after many uses, but you should check for scratches that can trap bacteria.

Wood and Foam

Wood racks look classic and feel sturdy. They do not react with most chemicals, but they can soak up liquids and need more care. You cannot autoclave wood racks, so cleaning takes longer. Foam racks hold tubes gently and work for short-term tasks, but they wear out quickly and do not resist chemicals well.

| Material | Durability | Chemical Resistance | Cleaning Ease | Best Use |

|---|---|---|---|---|

| Wood | Moderate | Moderate | Moderate | Light, dry storage |

| Foam | Low | Poor | Easy | Temporary tube holding |

Tip: Choose wood racks only for dry storage. For most Western Blotting steps, plastic or metal racks work better.

Choosing a Test Tube Rack

Lab Workflow Needs

You want your lab to run smoothly. Start by thinking about how you move samples during Western Blotting. If you work with many tubes at once, stackable or interlocking racks help you save space and keep samples organized. Color-coding racks or using clear labels makes it easy to find the right sample fast. You can also use racks with alphanumeric grids for quick identification.

Tip: Organize racks to prevent cross-contamination and make sample retrieval easier.

Safety matters in every lab. Racks that keep tubes upright lower the risk of spills or breakage. You should inspect racks often for cracks or damage. Handle racks gently to avoid accidents and keep your workspace safe.

Sample Volume and Tube Size

You need to match your rack to the number and size of tubes you use. If you process large batches, choose racks with higher capacity. For small tubes, like those used in pcr plate racks, select racks with tight spacing and secure holes. This prevents tubes from tipping or getting mixed up.

| Tube Size | Recommended Rack Type |

|---|---|

| 0.2–0.5 mL | PCR plate racks |

| 12–17 mm | Classic or stackable racks |

Always check that your rack fits the tubes you use most. This helps you avoid wasted space and keeps your workflow efficient.

Protocol Compatibility

Your Western Blotting protocol may require special steps. Some racks need to withstand high heat or harsh chemicals. Polypropylene racks work well for most chemicals and can be autoclaved. Metal racks handle high temperatures and last longer in busy labs.

When you plan for the future, think about these best practices:

- Clean racks regularly to prevent contamination.

- Label racks and tubes clearly to avoid confusion.

- Choose racks made from materials that fit your experiments.

- Inspect racks for damage and replace them if needed.

- Use color-coding for easy sample identification.

Budget also plays a role. Durable racks may cost more at first, but they last longer and keep your samples safer. You can future-proof your lab by picking racks that meet both current and future needs.

You have many choices when you select racks for Western Blotting. Each type and material offers unique benefits. Think about your workflow, sample size, and cleaning needs. Choose racks that fit your lab and keep your samples safe. For most labs, polypropylene or stainless steel racks work best. Review your current setup and upgrade if needed to improve your results.

FAQ

What size test tube rack should you use for Western Blotting?

You should match the rack to your tube size. Most Western Blotting labs use racks for 12–17 mm tubes. Check your protocol and tube type before you choose.

Can you autoclave all test tube racks?

No, you cannot autoclave every rack. Polypropylene and stainless steel racks handle autoclaving well. Wood and some acrylic racks do not survive high heat. Always check the manufacturer’s instructions.

How do you clean a test tube rack safely?

You should wash racks with mild soap and water. For deeper cleaning, use a lab-safe disinfectant. Autoclave racks if the material allows. Inspect racks for cracks or damage after cleaning.

Why do some racks have alphanumeric grids?

Alphanumeric grids help you track samples. You can label each tube spot with a letter and number. This system reduces mix-ups and makes your workflow faster.

What is the best material for a test tube rack in a busy lab?

Polypropylene and stainless steel work best. Both resist chemicals and last a long time. Polypropylene racks are light and easy to move. Stainless steel racks stay strong after many uses.